Case Analysis of Panasonic-Tesla Collaboration: Insights for Upstream and Downstream Cooperation in the Power Battery Industry Chain

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Based on the collected data, this in-depth analysis report is written for you.

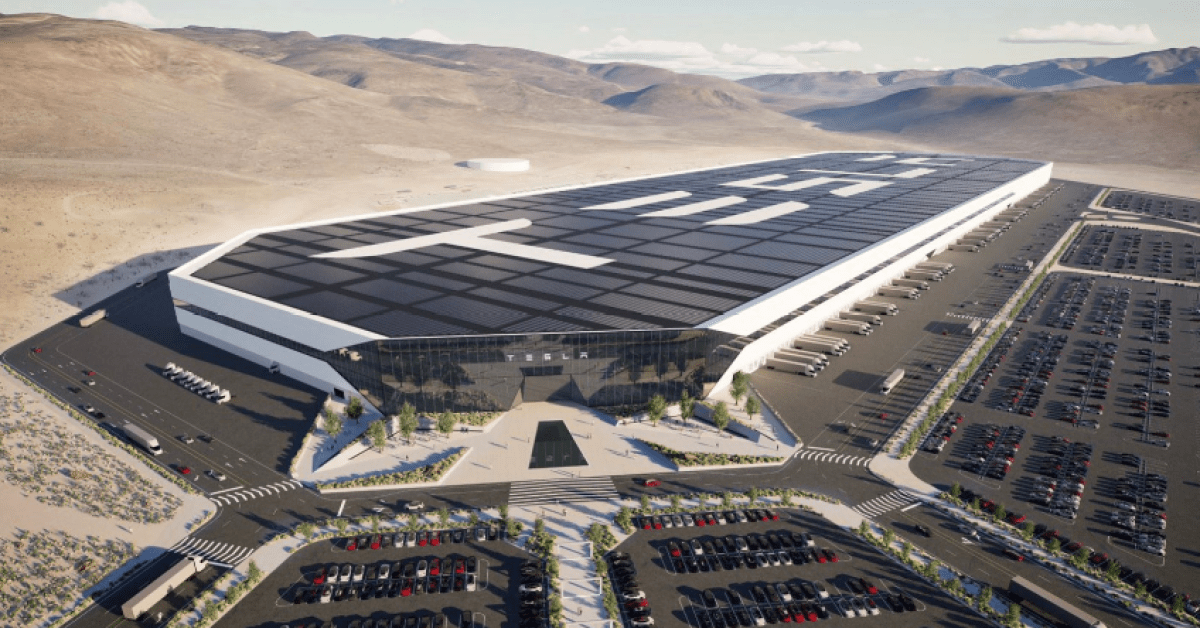

The collaboration between Panasonic and Tesla began in 2014, when the two companies announced the construction of the Gigafactory 1 in Sparks, Nevada. [1] At that time, Tesla was in a critical period with the hot sale of Model S and the upcoming mass production of Model 3, leading to a sharp increase in battery demand; while Panasonic, as a global leading battery manufacturer, had mature technology and production capacity. The two sides hit it off immediately: Panasonic committed to investing billions of dollars to build this ‘gigafactory’ with a target annual capacity of approximately 35 gigawatt-hours. [2]

This period saw their collaboration regarded as a model of upstream-downstream synergy in the electric vehicle industry chain. Panasonic provided battery technology and manufacturing capabilities, while Tesla offered stable orders and market demand commitments. The factory officially started production in 2016, mainly producing 2170-type lithium-ion batteries for Model 3 and subsequent models. This deeply bound joint venture model enabled resource sharing and risk co-sharing between the two companies, which was once considered a ‘match made in heaven’. [3]

As Tesla’s demand for capacity expansion accelerated, the contradictions between the two sides gradually surfaced. According to reports from the Wall Street Journal, there were serious differences in cost control, price negotiations, and capacity expansion pace. [4] Tesla CEO Elon Musk hoped Panasonic could further reduce battery prices and expand capacity to support its large-scale mass production plan; while Panasonic was cautious about continuous investment, worrying that overcapacity would lead to financial risks.

A deeper issue lay in cultural conflicts. Japanese enterprises emphasize stable operation, long-term planning, and lean management, while Tesla pursues rapid iteration, aggressive expansion, and cost control. Reports indicated that this ‘cultural conflict endangered the cooperative relationship between Tesla and Panasonic’. [4] Panasonic executives once publicly complained about Tesla’s payment terms and procurement strategies, while Tesla expressed dissatisfaction with Panasonic’s capacity response speed.

Entering 2021, the relationship between the two sides officially entered an ‘ice age’. Tesla began to accelerate its supplier diversification strategy, successively establishing cooperative relationships with battery manufacturers such as CATL, LG Energy Solution, and BYD. [5] In 2021, Tesla officially announced that it would include CATL in its battery supplier system for models produced in the Chinese market; meanwhile, LG Energy Solution’s factories in Poland and the United States also started supplying Tesla.

Facing the risk of order loss, Panasonic had to re-examine its business strategy. The company began to actively expand customers outside Tesla, while diversifying its technical route layout. In 2022, Panasonic announced that it would build a $4 billion power battery factory in Kansas, producing a new type of battery different from the products of the Nevada factory. [6] In addition, Panasonic announced at the CES exhibition that it would cooperate with Redwood Materials founded by JB Straubel to produce battery copper foil using recycled materials, reflecting its exploration in supply chain sustainability. [7]

From the perspective of commercial interests, the breakdown of Panasonic-Tesla collaboration stemmed from fundamental differences in their core demands. For Tesla, battery cost is a key factor determining the competitiveness of electric vehicles, and the company has always pursued extreme cost control; while Panasonic, as a listed company, needs to be responsible to shareholders and pursue reasonable profit margins and investment returns. When Tesla continued to demand price reductions, Panasonic’s profit margin was severely squeezed, and this conflict of interest demands was difficult to reconcile.

A deeper issue was the imbalance in bargaining power. Under the joint venture factory model, Panasonic invested a lot of fixed costs in the early stage, forming high sunk costs, which instead put it in a passive position in price negotiations. As an end customer, Tesla held the initiative in order allocation and could pressure price reductions by introducing new suppliers at any time. Panasonic was caught in a ‘dilemma’—continuing cooperation meant meager profits, while terminating cooperation meant the loss of early investments.

In terms of technical routes, Tesla has always pursued technological innovation and differentiation. In 2020, Tesla released the 4680 large cylindrical battery technology at its ‘Battery Day’ event, which is a brand-new battery specification with higher energy density and lower cost than the existing 2170 battery. However, Panasonic’s production line in Nevada was mainly designed for the 2170 battery, and upgrading and transforming it required huge investment and technical risks.

Misalignment in capacity planning was also prominent. Tesla’s capacity expansion plan was aggressive, requiring suppliers to respond quickly and expand capacity; while Panasonic, as a traditional Japanese enterprise, preferred a stable capacity ramp-up strategy. This rhythm difference led to frequent frictions in capacity targets. Tesla once publicly criticized Panasonic’s capacity expansion speed for failing to meet its needs, while Panasonic retorted that Tesla’s demand forecast was too optimistic.

From Tesla’s strategic perspective, over-reliance on a single supplier poses huge supply chain risks. During the 2020 COVID-19 pandemic, the risk of supply chain disruption became more prominent, prompting Tesla to accelerate supplier diversification. By introducing multiple suppliers, Tesla could not only分散 supply risks but also enhance bargaining power and improve the resilience and security of the supply chain.

In addition, Tesla’s desire to control core technologies also promoted the transformation of its supply chain strategy. As the core component of electric vehicles, the technological progress and cost reduction of batteries directly determine product competitiveness. Tesla hoped to accelerate technological innovation and cost reduction by supporting multiple suppliers to form a competitive pattern. At the same time, the company was also secretly promoting its self-developed battery plan to further enhance the autonomous control capability of the supply chain.

The Panasonic-Tesla case deeply reveals the potential risks of over-reliance on a single supplier. For vehicle manufacturers, the stability and economy of battery supply are directly related to the market competitiveness and profitability of products. When Tesla concentrated most of its battery purchases on Panasonic, although it enjoyed initial scale effects and synergy advantages, it also埋下 the hidden danger of supply chain fragility. Once the cooperative relationship has problems, the vehicle manufacturer will face serious supply interruption risks.

Similarly, for battery suppliers, over-reliance on a single customer also has huge operational risks. Panasonic had a high degree of business dependence on Tesla, and when Tesla turned to other suppliers, Panasonic’s revenue and profits were significantly impacted. Therefore, both vehicle manufacturers and battery enterprises should pay attention to the diversification of customer structure and supplier structure while pursuing scale effects, avoiding ‘putting all eggs in one basket’.

The traditional joint venture factory model can achieve resource sharing and risk co-sharing, but it also has problems such as insufficient flexibility and difficulty in interest coordination. Panasonic-Tesla’s Gigafactory 1 is a typical representative of this model—both sides enjoyed cooperation dividends in the early stage, but as the market environment changed and interest demands diverged, this deeply bound model became a ‘shackle’ for both sides.

Future industry chain cooperation models should be more flexible and diverse. On one hand, we can explore a mixed model of ‘strategic cooperation + diversified supply’, maintaining a strategic cooperative relationship with core suppliers while retaining the flexibility to introduce other suppliers; on the other hand, we can consider more loose forms of cooperation such as joint R&D, technology licensing, and capacity sharing, which can achieve synergy effects while maintaining各自 strategic independence.

Battery technology is in a period of rapid iteration, with new battery technologies emerging continuously. How to coordinate the choice of technical routes and the pace of capacity investment is one of the core challenges of upstream-downstream cooperation in the industry chain. In the Panasonic-Tesla case, the release of the 4680 battery became an important turning point in their relationship—Tesla hoped to switch to the new technology quickly, while Panasonic faced the risk of huge depreciation of existing assets.

To avoid similar conflicts, upstream and downstream of the industry chain should establish more perfect technical route coordination and investment protection mechanisms. Specific measures include: clarifying the transition arrangements and cost-sharing methods for technical iteration in cooperation agreements; establishing a joint evaluation mechanism to regularly review the development prospects of technical routes; setting up investment compensation mechanisms to protect the reasonable rights and interests of early investors.

The sustainability of industry chain cooperation depends on the fairness and rationality of the interest distribution mechanism. In Panasonic-Tesla cooperation, the contradictions between the two sides in cost control and profit distribution became increasingly sharp, eventually leading to the breakdown of the cooperative relationship. This reminds us that industry chain cooperation must establish a clear and transparent interest distribution mechanism and adjust it in time with changes in the market environment.

Specifically, we can start from the following aspects: First, clearly stipulate the cost accounting method and pricing mechanism in the cooperation agreement to reduce disputes caused by information asymmetry; Second, establish a profit sharing or risk compensation mechanism to share excess profits when the market is booming and bear losses together when the market is downturn; Finally, form a closer interest binding through cross-shareholding, joint investment, etc., to enhance the stability of the cooperative relationship.

Against the background of global supply chain restructuring, supply chain security and strategic autonomy have become the focus of attention of countries and enterprises. The Panasonic-Tesla case shows that excessive supply chain dependence may become a strategic shortcoming. Vehicle manufacturers need to consider establishing certain autonomous capabilities in core components to cope with potential supply interruption risks.

However, complete self-sufficiency is neither economical nor realistic. A more pragmatic strategy is: while maintaining strategic cooperative relationships with core suppliers, enhance the resilience and anti-risk ability of the supply chain through multiple means such as diversified procurement, self-developed technology, and recycling. Tesla currently adopts this strategy—cooperating with external suppliers such as CATL and LG while continuing to promote its self-developed battery plan.

For Chinese new energy vehicle enterprises, the Panasonic-Tesla case provides an important warning. It is suggested that vehicle manufacturers take the following measures in their battery supply strategy:

First, establish a diversified supplier system to avoid over-reliance on a single supplier. According to the needs of different models and markets, configure 2-3 core suppliers to form an effective competitive pattern and supply redundancy.

Second, strengthen strategic collaboration with suppliers. Through joint R&D, capacity pre-locking, equity cooperation, etc., establish a closer cooperative relationship with core suppliers while maintaining necessary flexibility.

Third, appropriately layout self-developed capabilities. For large-scale vehicle manufacturers, they can consider investing resources in battery technology R&D. Although it is difficult to achieve full self-supply in the short term, it can enhance their voice in supplier negotiations and lay the foundation for possible vertical integration in the future.

For Chinese power battery enterprises, they should not only seize market opportunities to expand their share but also guard against risks caused by excessive customer concentration.

First, actively expand customer structure. In addition to serving domestic vehicle manufacturers, they should also actively explore overseas markets and establish cooperative relationships with mainstream global automakers to avoid over-reliance on a single customer or market.

Second, continue to increase R&D investment and build technical moats. The power battery industry has rapid technological iteration, and only by maintaining technical leading advantages can we stand firm in the fierce market competition.

Third, appropriately extend the industry chain layout. Enhance the autonomous control capability of the supply chain and reduce the impact of raw material price fluctuations through upstream resource integration and recycling layout.

From the perspective of industry development, the Panasonic-Tesla case also reflects the trend of intensified upstream-downstream game in the industry chain. Excessive competition not only damages the interests of both sides but also is not conducive to the healthy development of the industry.

It is suggested that industry organizations, regulatory authorities, etc. actively guide upstream and downstream of the industry chain to establish a more rational and healthy cooperative relationship. Specific measures include: establishing an industry information sharing mechanism to reduce misunderstandings and conflicts caused by information asymmetry; promoting the formulation of industry standards and cooperation norms to provide institutional guarantees for industry chain cooperation; encouraging leading enterprises to lead the establishment of industrial alliances to promote resource integration and collaborative innovation.

The journey of Panasonic and Tesla from ‘honeymoon’ to ‘parting ways’ is a classic case of upstream-downstream cooperation game in the power battery industry chain. This case deeply reveals core issues such as single dependence risk, cooperation model innovation, interest coordination mechanism, technical iteration response, and supply chain security.

For upstream and downstream enterprises in the industry chain, future cooperation should abandon the simple ‘deep binding’ thinking and shift to a more flexible, mutually beneficial, and win-win cooperation model. Vehicle manufacturers need to build diversified supply systems, battery enterprises need to expand customer structure and strengthen technical advantages, and both sides need to establish more perfect interest sharing and risk co-sharing mechanisms. Only by cooperating in competition and winning together in cooperation can we promote the sustained and healthy development of the entire industry.

[1] Forbes - ‘Inside Tesla’s Gigafactory: A Crazy Idea Takes Shape In Nevada’ (https://www.forbes.com/sites/joannmuller/2016/07/27/inside-teslas-gigafactory-a-crazy-idea-takes-shape-in-nevada/)

[2] Wall Street Journal Chinese Edition - ‘Tesla’s Former CTO Embarks on High-Difficulty New Venture, Expected to Reduce Electric Vehicle Prices’ (https://cn.wsj.com/articles/特斯拉前CTO投身高难度新事业-有望降低电动车价格)

[3] Forbes - ‘Why Tesla Could Become The Netflix Of The EV Market’ (https://www.forbes.com/sites/petercohan/2022/05/19/why-tesla-could-become-the-netflix-of-the-ev-market/)

[4] Wall Street Journal Chinese Edition - ‘Cultural Conflict Endangers Tesla-Panasonic Cooperative Relationship’ (https://cn.wsj.com/articles/文化冲突危及特斯拉与松下的合作关系)

[5] Forbes - ‘GM Topped Tesla To Become One Of The Fastest-Growing EV Makers’ (https://www.forbes.com/sites/alanohnsman/2025/01/27/gm-topped-tesla-ev-growth/)

[6] Wall Street Journal Chinese Edition - ‘Tesla Battery Supplier Panasonic Plans to Build $4 Billion Power Battery Factory in Kansas’ (https://cn.wsj.com/articles/panasonic-energy与堪萨斯州合作兴建40亿美元的电动汽车电池工厂)

[7] Forbes - ‘Panasonic To Make Tesla Battery Cells With Recycled Material From JB Straubel’s Redwood’ (https://www.forbes.com/sites/alanohnsman/2022/01/04/panasonic-to-make-tesla-battery-cells-with-recycled-material-from-jb-straubels-redwood/)

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.