Analysis of the Labor Cost Saving Effect of Intelligent Transformation in Muyuan's Pig Farms

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Related Stocks

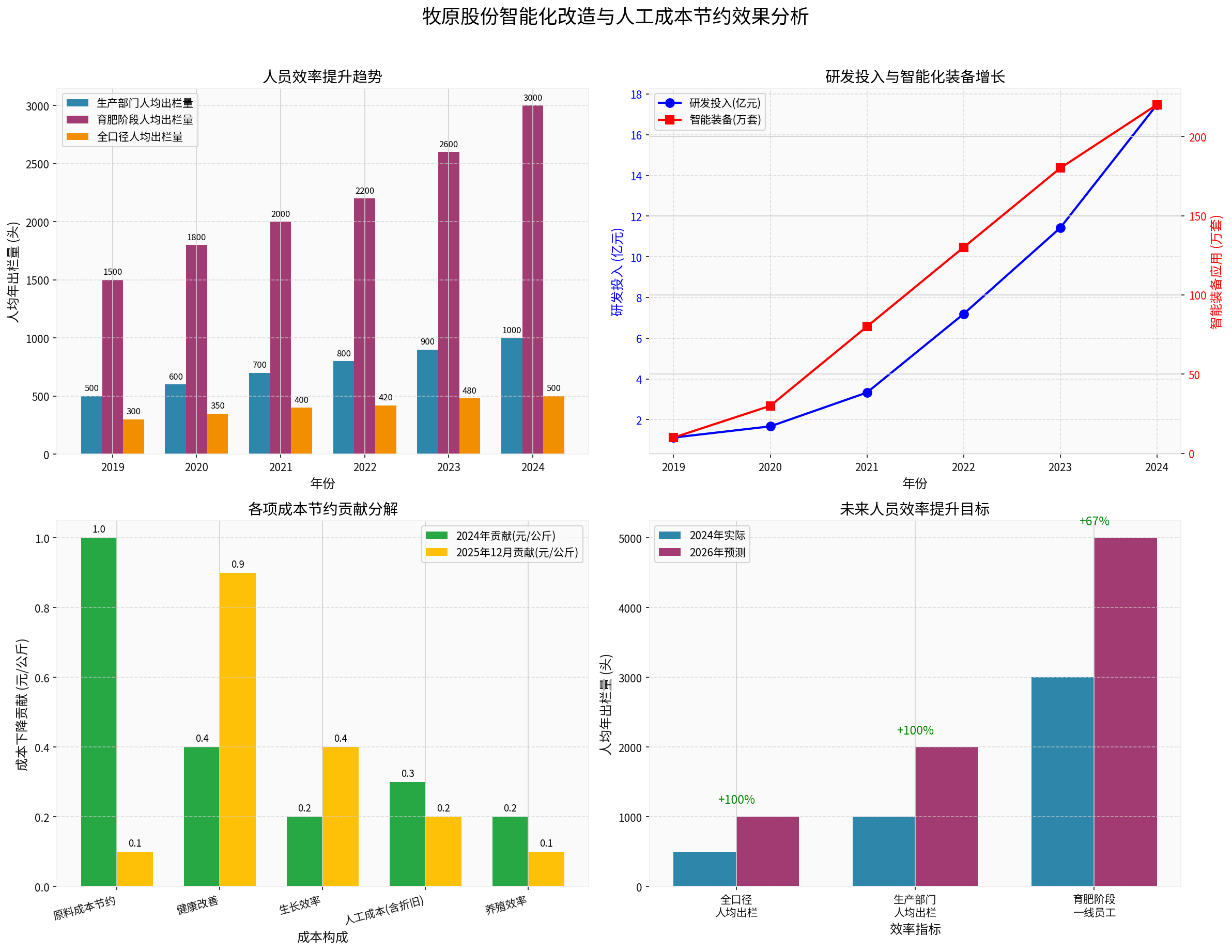

Muyuan Co., Ltd. (Stock Code: 002714.SZ) as a leading enterprise in China’s pig farming industry, has continued to increase R&D investment to promote intelligent transformation in recent years. The company’s R&D expenses have continued to grow from RMB 112 million in 2019 to RMB 1.747 billion in 2024. The number of full-time R&D personnel has risen to 6,486, and together with technical personnel, the total number reaches 10,000. The company has applied for 2,276 national patents in total [0][1]. As of 2024, the company has deployed over 2.2 million sets of intelligent equipment in all links of breeding production, including systems such as intelligent environmental control, intelligent feeding, intelligent inspection, and Pig Cough Management, achieving full coverage of 100% of pig houses [0][1].

Muyuan’s intelligent transformation originated from the urgent need for African swine fever (ASF) prevention and control. Before the ASF outbreak in 2018, the company’s R&D personnel even lay inside pig houses to experience the environmental control effect. The trial-and-error cost during the optimization and debugging stage alone exceeded RMB 12 billion. Eventually, the company successfully developed intelligent air-filtered pig houses, which effectively withstood the impact of ASF [1]. This technological breakthrough established Muyuan’s leading position in the field of intelligent pig farming.

Muyuan has built a complete intelligent pig farming technology system covering the entire breeding process:

| Technology System | Function Description | Application Scope |

|---|---|---|

| Intelligent Environmental Control System | Independently developed air-filtered pig houses, intelligently adjusts temperature and humidity, independent ventilation for individual pigs | 100% pig house coverage |

| Intelligent Feeding System | One formula per day, AI-generated recipes, precise feeding control to the gram | 100% pig house coverage |

| Intelligent Inspection Robot | 17 health detection items including body temperature, diarrhea, piloerection, and trauma | 85% pig house coverage |

| Pig Cough Management System | Disease early warning through voice recognition | 80% pig house coverage |

| IoT Platform | Integrates data from 3.3 million sets of equipment, generates 2 billion pieces of monitoring data daily | 100% coverage |

| AI Large Model Application | Local deployment of DeepSeek, improves decision-making efficiency | Pilot promotion (30%) |

Muyuan’s R&D investment has shown a sustained high-growth trend. From 2019 to 2024, R&D expenses increased from RMB 112 million to RMB 1.747 billion, with a compound annual growth rate (CAGR) of over 70% [0][1]. The full-time R&D team has expanded from 500 to 6,486 people, with over 1,200 algorithm engineers in the core technical team. The company has built innovation platforms in Shenzhen, Zhengzhou, Nanyang and other places, and among its 130,000 employees, over 40,000 have a bachelor’s degree or above [1].

The number of intelligent equipment deployed has grown from 100,000 sets in 2019 to 2.2 million sets in 2024, achieving intelligent coverage of all links in breeding production [0]. Currently, Muyuan’s intelligent systems dynamically monitor over 4,500 indicators daily, generating over 2 billion pieces of various data, which are integrated into the big data platform for refined management [1].

The most direct effect of intelligent transformation is reflected in the significant improvement of labor efficiency. According to data analysis:

| Efficiency Indicator | 2019 | 2024 | Growth Rate |

|---|---|---|---|

| Full-caliber Annual Number of Pigs Sold per Employee | 300 pigs | 500 pigs | +67% |

| Annual Number of Pigs Sold per Employee in Production Department | 500 pigs | 1,000 pigs | +100% |

| Annual Number of Pigs Sold per Front-line Employee in Fattening Stage | 1,500 pigs | 3,000 pigs | +100% |

The data shows that Muyuan has achieved a doubling of labor efficiency through intelligent transformation. In particular, the number of pigs managed per employee in the production department and front-line employees in the fattening stage has both increased by 100% [0][1]. This means that the company’s production capacity has increased significantly while the number of employees remains basically stable.

According to institutional forecasts, Muyuan’s labor efficiency will continue to improve [0][1]:

| Efficiency Indicator | 2024 Actual | 2025 Forecast | 2026 Forecast | Three-year Growth |

|---|---|---|---|---|

| Full-caliber Annual Number of Pigs Sold per Employee | 500 pigs | 700 pigs | 1,000 pigs | +100% |

| Annual Number of Pigs Sold per Employee in Production Department | 1,000 pigs | 1,500 pigs | 2,000 pigs | +100% |

| Annual Number of Pigs Sold per Front-line Employee in Fattening Stage | 3,000 pigs | 4,000 pigs | 5,000 pigs | +67% |

These forecasts show that by 2026, Muyuan’s labor efficiency will double compared to 2024, further consolidating its industry-leading cost advantage [0].

Muyuan Co., Ltd.'s average full breeding cost in 2024 was RMB 12.04 per kg, a decrease of RMB 2.06 per kg compared to 2024. Among them, labor costs (including depreciation and amortization) contributed to a cost reduction of RMB 0.3 per kg, accounting for 14.5% of the total cost reduction contribution [0].

In December 2025, the monthly cost decreased by RMB 1.6 per kg, of which labor costs (including depreciation and amortization) contributed to a reduction of RMB 0.2 per kg [0]. The specific decomposition is as follows:

| Cost Component | 2024 Full-year Contribution to Cost Reduction (RMB/kg) | December 2025 Contribution to Cost Reduction (RMB/kg) |

|---|---|---|

| Raw Material Cost Saving | 1.00 | 0.10 |

| Health Improvement | 0.40 | 0.90 |

| Growth Efficiency | 0.20 | 0.40 |

Labor Costs (including depreciation and amortization) |

0.30 |

0.20 |

| Breeding Efficiency | 0.20 | 0.10 |

Since 2020, Muyuan has achieved a cumulative cost reduction of over RMB 300 per pig through full-chain intelligent transformation [1]. Based on the company’s 71.6 million pigs sold in 2024, the annual cost savings brought by intelligence exceed RMB 20 billion. Among them, labor cost saving is an important component.

For 2026, the company expects labor costs to continue to decrease by RMB 0.2-0.3 per kg, driven mainly by: the dilution of depreciation and labor costs due to the growth of pig sales, and the continuous improvement of labor efficiency [0].

The labor cost saving effect of Muyuan’s intelligent transformation is transmitted through the following mechanisms:

-

Automation Replaces Manual Labor: Equipment such as intelligent feeding systems and inspection robots replaces a large number of manual operations, reducing the demand for front-line personnel.

-

Improved Per Capita Management Capacity: Intelligent systems enable a single employee to manage more pigs, increasing from 1,500 pigs per employee in the fattening stage to 3,000 pigs.

-

Remote Monitoring Reduces Inspection Frequency: The IoT platform realizes remote monitoring, reducing the frequency and time of on-site manual inspections.

-

AI Early Warning Reduces Emergency Handling: Intelligent health management systems and the Pig Cough Management System provide early disease warnings, reducing the workload of manual emergency handling.

Muyuan’s breeding cost continues to lead the industry average:

| Time Node | Muyuan’s Full Cost (RMB/kg) | Industry Average (RMB/kg) | Lead Margin |

|---|---|---|---|

| 2024 Full Year | 12.04 | 14.50 | 2.46 |

| December 2025 | 11.60 | Approx. 14.10 | 2.50+ |

This cost leadership advantage mainly comes from Muyuan’s comprehensive technological advantages in intelligence, breeding, nutrition, disease prevention and control, etc. [0][1].

In terms of labor efficiency, Muyuan far exceeds the industry average:

| Indicator | Muyuan Co., Ltd. | General Industry Level |

|---|---|---|

| Annual Number of Pigs Sold per Front-line Employee in Fattening Stage | 3,000 pigs | 500-1,000 pigs |

| Labor Efficiency Growth Rate | Annual average +15-20% | Annual average +5-8% |

Intelligent transformation has enabled Muyuan’s labor efficiency to reach 3-6 times the industry average, forming a significant competitive advantage [0][1].

Muyuan’s independently developed fresh air filtration system uses a high-efficiency precision filter of MERV16 level, which is close to ICU standards. Fresh air is filtered through 4 layers, completely isolating particles with a diameter greater than 0.3 microns, effectively blocking viruses. The intelligent environmental control system realizes full-process intelligent management from the air inlet to the air outlet of the pig house. The air entering the house is filtered through four layers, and the air exiting the house is treated with a sterilization and deodorization system, filtering and killing 99.9% of airborne bacteria [1].

Muyuan’s intelligent feeding system realizes precise nutrition supply with “one formula per day”. Based on changes in the raw grain market and the growth needs of pigs, the AI system automatically generates the optimal feed formula, with feeding control precise to the gram. The company also applies low-soybean diet technology, reducing the soybean meal addition from 13% to about 5%, and its 30,000-ton annual output synthetic amino acid project has been put into operation, effectively reducing feed costs [1].

Track-mounted inspection robots shuttle back and forth on the top of pig houses, and can complete 17 items of full-body physical examinations including body temperature, presence of diarrhea, piloerection, and trauma. The test results are pushed to breeders’ mobile phones in real time, enabling early prediction of the health status of the pig herd. The Pig Cough Management System conducts early disease warning through voice recognition technology, and immediately alerts once abnormalities are detected [1].

In 2025, Muyuan took the lead in completing the local deployment of the DeepSeek large model and applied it to production management. The AI large model is like a “super brain” responsible for command and dispatch; various sensors such as monitors, microphones, and temperature and humidity sensors are like “five senses”, real-time perceiving the pig house environment; feeding, sewage cleaning facilities and various pipelines are like “hands and feet”, operating the daily operation of the pig house day and night [1].

Through years of continuous intelligent transformation, Muyuan Co., Ltd. has achieved remarkable results in labor cost saving:

-

Doubled Labor Efficiency: The annual number of pigs sold per employee in the production department increased from 500 to 1,000, and that in the fattening stage rose from 1,500 to 3,000, both achieving 100% growth.

-

Significant Cost Savings: In 2024, labor costs (including depreciation and amortization) contributed to a cost reduction of RMB 0.3 per kg. Since 2020, the cumulative cost reduction per pig has exceeded RMB 300.

-

Improved Technology System: A complete technology system covering intelligent environmental control, intelligent feeding, intelligent inspection, and IoT platform has been built, with 2.2 million sets of intelligent equipment deployed.

-

Sustained Cost Reduction Expected: In 2026, labor costs are expected to continue to decrease by RMB 0.2-0.3 per kg, and the labor efficiency target will achieve doubled growth.

Muyuan’s intelligent transformation has set a benchmark for the pig farming industry. With the continuous improvement of intelligent level, the company’s labor efficiency and cost advantages are expected to further expand. The breeding cost is expected to drop to RMB 10.2-10.3 per kg (quarterly average) in 2026, continuing to maintain its industry-leading cost position [0].

The company plans to increase its dividend ratio to no less than 40% starting from 2024, a significant increase compared to the previous average dividend rate of 28%, which significantly enhances its dividend attribute [0]. For investors focusing on the pig farming sector, as an industry leader, Muyuan’s cost advantages brought by intelligent transformation deserve focused attention.

[0] Jinling API Data - Muyuan Co., Ltd. Company Profile, Financial Analysis, Market Data

[1] Xinhua News Agency - “Raising Ten Million Pigs Digitally: Unlocking the ‘Intelligent’ Transformation Code of Muyuan Co., Ltd.” (http://www.news.cn/fortune/20251218/37f761d9c4cb4faf9890c12fee69015a/c.html)

[2] OFweek Weikehao - “How Many Surprises Are Hidden in Muyuan’s 2024 Financial Report?” (https://mp.ofweek.com/finance/a756714983517)

[3] Xueqiu - “Muyuan Co., Ltd. 2025 Cost Summary” (https://xueqiu.com/1632625377/370634798)

[4] Eastmoney.com - “In-depth Research Report on Muyuan Co., Ltd. (002714.SZ)” (https://pdf.dfcfw.com/pdf/H3_AP202404091630067749_1.pdf)

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.