In-Depth Analysis Report on the Hydrogen-Carbon Co-Production Industry Chain 2026

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Based on the latest searched information, I now present to you a

The team led by Researcher Yu Qingkai from the Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences (CAS), has made a major breakthrough in hydrogen-carbon co-production technology. Supported by the National Key R&D Program, the team focuses on the R&D and industrialization of

- Continuous Operation of Pyrolysis Reactor:The team is tackling the continuous operation issue of the pyrolysis reactor, aiming to increase the stable continuous operation time toone month[1]

- Zero-Pollution Hydrogen Production Technology:The developed pyrolysis technology can simultaneously produce high-purity hydrogen and graphite under nearly zero-pollution operating conditions [1]

- Technical Advantage Comparison:Compared with traditional high-pollution hydrogen and carbon production processes, this technology not only avoids greenhouse gas emissions but also has greater cost and efficiency advantages in distributed scenarios such as chemical industry and hydrogen refueling stations [1]

Methane pyrolysis for hydrogen production is a process that directly cracks methane (the main component of natural gas) into hydrogen and solid carbon:

$$\text{CH}_4 \rightarrow \text{C} + 2\text{H}2 \quad \Delta H^\circ{298K} = +74.85 \text{ kJ/mol}$$

| Indicator | Traditional SMR Process | Methane Pyrolysis Process | Water Electrolysis for Hydrogen Production |

|---|---|---|---|

| CO₂ Emissions | 11 kg/kg H₂ | 0-2 kg/kg H₂ | 0 kg/kg H₂ |

| Relative Cost Index | 100% | ~60% | ~150% |

| Hydrogen Purity | Medium (requires purification) | High | Ultra-High |

Compared with the traditional steam methane reforming (SMR) process, the methane pyrolysis for hydrogen production process can reduce greenhouse gas emissions by

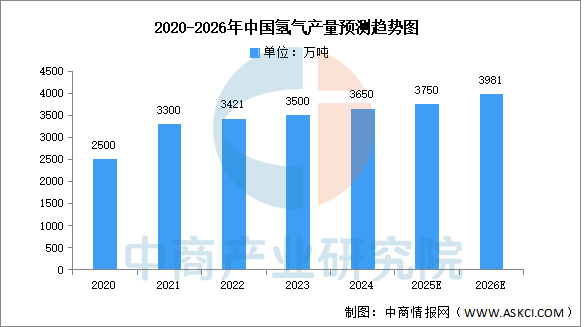

According to data from the China Business Industry Research Institute, as of the end of 2024, China’s annual hydrogen output reached

- 2025: Expected to reach 37.5 million tons

- 2026: Expected to increase to 39.81 million tons[3]

According to the forecast of the China Hydrogen Energy Alliance:

- 2030:Annual hydrogen demand will reach37.15 million tons, accounting for about 5% of terminal energy consumption

- 2060:Annual hydrogen demand will increase to approximately130 million tons, accounting for about 20% of terminal energy consumption [3]

- Upstream (Hydrogen Production): 40%

- Midstream (Storage and Transportation): 25%

- Downstream (Application): 25%

- Carbon Materials (By-Product): 10%

The main current hydrogen production processes include:

| Technology Type | Proportion | Carbon Emission Characteristics |

|---|---|---|

| Gray Hydrogen (Fossil Fuel-Based Hydrogen Production) | Dominant | High Emissions |

| Blue Hydrogen (With Carbon Capture) | Gradual Growth | Medium Emissions |

| Green Hydrogen (Renewable Energy Electrolysis) | Rapid Growth | Zero Emissions |

| Hydrogen-Carbon Co-Production (Methane Pyrolysis) | Emerging Technology | Near-Zero Emissions |

Hydrogen energy storage and transportation is a key bottleneck for industrial development:

- High-Pressure Gaseous Storage and Transportation:Current mainstream solution, mature technology but limited hydrogen storage density

- Cryogenic Liquid Storage and Transportation:High hydrogen storage density, but high energy consumption and cost

- Pipeline Hydrogen Transportation:Low cost, large transportation volume, but high construction investment

- Organic Liquid Hydrogen Storage:Good safety, but technology is not yet mature [3]

As of the end of 2024, China has built a total of

-

Transportation Sector:Hydrogen Fuel Cell Vehicles

- In 2024, the production and sales of fuel cell vehicles were 5,548 units and 5,405 units respectively

- Production is expected to reach 5,877 units in 2026 [3]

-

Industrial Sector:Chemical Raw Materials, Metallurgical Decarbonization

-

Power Generation and Energy Storage:Distributed Energy Systems

-

Building Heating:Hydrogen Energy Combined Heat and Power

The carbon materials produced during methane pyrolysis for hydrogen production have high added value:

| Carbon Material Type | Application Field | Market Value |

|---|---|---|

| Graphene | Electronic Devices, Composite Materials | High |

| Carbon Nanotubes | Battery Electrodes, Supercapacitors | High |

| Graphite | Lubricants, Refractory Materials | Medium |

| Carbon Black | Rubber, Tires, Coatings | Medium |

Taking biomethane resources as an example:

- Potential Biomethane Capacity: 160 million cubic meters

- With 20% utilization rate, annual hydrogen production can reach over 60 million cubic meters(estimated at 20 RMB/kg, revenue is about 120 million RMB)

- Co-produced Nano-Carbon: over 16,000 tons(estimated at 6,000 RMB/ton, revenue is about 100 million RMB)

- Total Annual Revenue: Approximately 220 million RMB, with CO₂ emission reduction of about 66,000 tons [4]

- Short-Term (Within 6 Months):Overcome technical bottlenecks such as continuous system operation

- Mid-Term (1-2 Years):Promote the industrialization of the technology

- 2026:Implement demonstration applications in Sichuan Province, which is rich in natural gas resources [1]

- Carry out large-scale production in natural gas-producing areas

- Promote distributed hydrogen production in the chemical industry with high hydrogen demand

- Promote the layout of a national distributed hydrogen production network at hydrogen refueling stations [1]

- C-Zero (US): Molten metal-catalyzed methane pyrolysis for hydrogen production

- Wintershall Dea (Europe) and Karlsruhe Institute of Technology (Germany): Jointly advancing molten metal-catalyzed methane pyrolysis

- HiiROC (UK): Secured investment from VNG Group to advance commercialization

- BASF: Jointly developing methane pyrolysis technology with partners, and a pilot reactor is already in operation at its Ludwigshafen base in Germany [2]

- Shanghai Qingtian New Materials Technology Co., Ltd.: Promoting large-scale production of clean hydrogen and high-purity carbon materials

- Team led by Professor Zhou Ying from Southwest Petroleum University: Developed a series of catalysts and processes for molten-process methane pyrolysis for hydrogen production and high-value carbon materials [2]

- 2024 Market Scale: 5.99 billion RMB

- 2025 Forecast: 6.8 billion RMB

- 2026 Forecast: Over 7 billion RMB[3]

- 2024 Production: 5,548 units

- 2026 Forecast Production: 5,877 units [3]

- 15th Five-Year Plan Period (2026-2030):Hydrogen energy industrialization will accelerate driven by policies

- Central Enterprise Demonstration Projects:Account for more than 60%, leading industry development

- Accelerated Replacement of Gray Hydrogen with Green Hydrogen:Target capacity exceeds 40GW in 2025 [3]

- EU CBAM Mechanism:Carbon tax imposed on the shipping sector starting from 2024; free quotas for the aviation sector will be phased out in 2026

- Domestic Carbon Price:In May 2025, China’s carbon emission allowances (CEA) fluctuated at 70 RMB/ton CO₂

- Driven by Carbon Costs:Markets for green hydrogen and hydrogen-based fuels expand, and new scenarios for industrial decarbonization emerge [5]

- Core technological breakthroughs (continuous operation of pyrolysis reactors)

- Equipment homogenization issue

- Overseas certification barriers

- High terminal application costs

- Cross-field technology integration (e.g., chemical industry coupling)

- Construction of discourse power in international standards

- Business model innovation (e.g., hydrogen bank)

- Cost reduction brought by the expansion of green hydrogen pipelines [5]

| Field | Investment Recommendation | Key Focus Points |

|---|---|---|

| Hydrogen Production Equipment | Key Focus | Energy consumption reduction of electrolyzer technology, AI-optimized power consumption |

| Storage and Transportation Facilities | Focus on Pipelines | Technological breakthroughs in liquid hydrogen storage and transportation |

| Carbon Materials | Long-Term Layout | High-value applications of graphene and carbon nanotubes |

| Fuel Cells | Cautiously Optimistic | Cost reduction speed, promotion progress |

- Hydrogen-carbon co-production technology will be implemented in demonstration applications in Sichuan and other regions

- The continuous operation time of pyrolysis reactors is expected to exceed one month

- Demonstration projects will verify the technical feasibility and economic viability

- Large-scale commercial promotion

- Further improvement of cost competitiveness

- Formation of a value chain for co-produced carbon materials

- Hydrogen energy accounts for 20% of terminal energy consumption

- Green hydrogen output is expected to exceed 100 million tons

- Hydrogen-carbon co-production becomes one of the mainstream hydrogen production routes

2026 is a pivotal year for the industrialization of hydrogen-carbon co-production technology. The technological breakthrough by the team led by Yu Qingkai from the Shanghai Institute of Microsystem and Information Technology, CAS, has laid an important foundation for the commercial application of hydrogen-carbon co-production technology. This technology achieves “zero-carbon” hydrogen production via direct methane pyrolysis, while co-producing high-value-added carbon materials, and has significant advantages in terms of cost, efficiency, and environmental protection.

Driven by the “Dual Carbon” goals, with the improvement of technological maturity, collaborative innovation across the industry chain, and continuous policy support, hydrogen-carbon co-production technology is expected to become an important pathway for green hydrogen energy development. It is anticipated to achieve large-scale application in fields such as chemical industry, hydrogen refueling stations, and distributed energy, providing important support for China’s energy transition and the achievement of carbon neutrality goals.

[1] China News Service - “Chinese Scientists Break Through Hydrogen-Carbon Co-Production Technology, Zero-Pollution Hydrogen Production Facilitates Energy Transition” (https://www.chinanews.com.cn/gn/2026/01-18/10554059.shtml)

[2] Research Progress on Methane Pyrolysis for Hydrogen Production and Carbon Material Processes, Low-Carbon Chemistry and Chemical Engineering (https://www.dthxyhg.com/rc-pub/front/front-article/download/56856105/lowqualitypdf/)

[3] The Paper - “2025 China Hydrogen Energy Industry Chain Map and Investment Layout Analysis” (https://m.thepaper.cn/newsDetail_forward_32286878)

[4] Shanghai Jiao Tong University - “Natural Gas Pyrolysis for Hydrogen Production and Co-Produced Nano-Carbon Material Technology” (https://aitri.sjtu.edu.cn/ach/info/9b490d65-9afb-4c64-a710-38f78766da81)

[5] Hwatai Securities - “Hydrogen Energy Industry is Expected to Mature, Focus on Opportunities for Equipment and Operators” (https://pdf.dfcfw.com/pdf/H3_AP202507021701755247_1.pdf)

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.