Enjie Co., Ltd. (SZ002812) In-Depth Analysis Report on Lithium Battery Separator Technology Advantages

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Related Stocks

Based on the collected information, I have prepared an in-depth analysis report on the separator technology advantages of Enjie Co., Ltd. (SZ002812).

Enjie Co., Ltd. (Yunnan Enjie New Materials Co., Ltd., 002812.SZ) is the absolute leader in the global lithium battery separator industry[0]. According to the first half of 2025 annual report, the operating revenue of the company’s lithium battery separator products accounts for 83.64% of total revenue, solidifying its strategic core position[1]. The company has ranked first in the wet-process lithium battery separator market for seven consecutive years, and once again topped the “Annual Competitive Brand List for Separators in China’s Lithium Battery Industry” in 2025[2].

As of the end of 2024, Enjie Co., Ltd.'s separator production capacity was approximately 11.7 billion square meters, with a plan to exceed 15 billion square meters of global lithium battery separator capacity by 2025[2]. The company has established a global layout with 11 domestic bases and 2 overseas bases (Hungary, the United States), with overseas revenue accounting for more than 20%, demonstrating strong risk resistance in the global market[2].

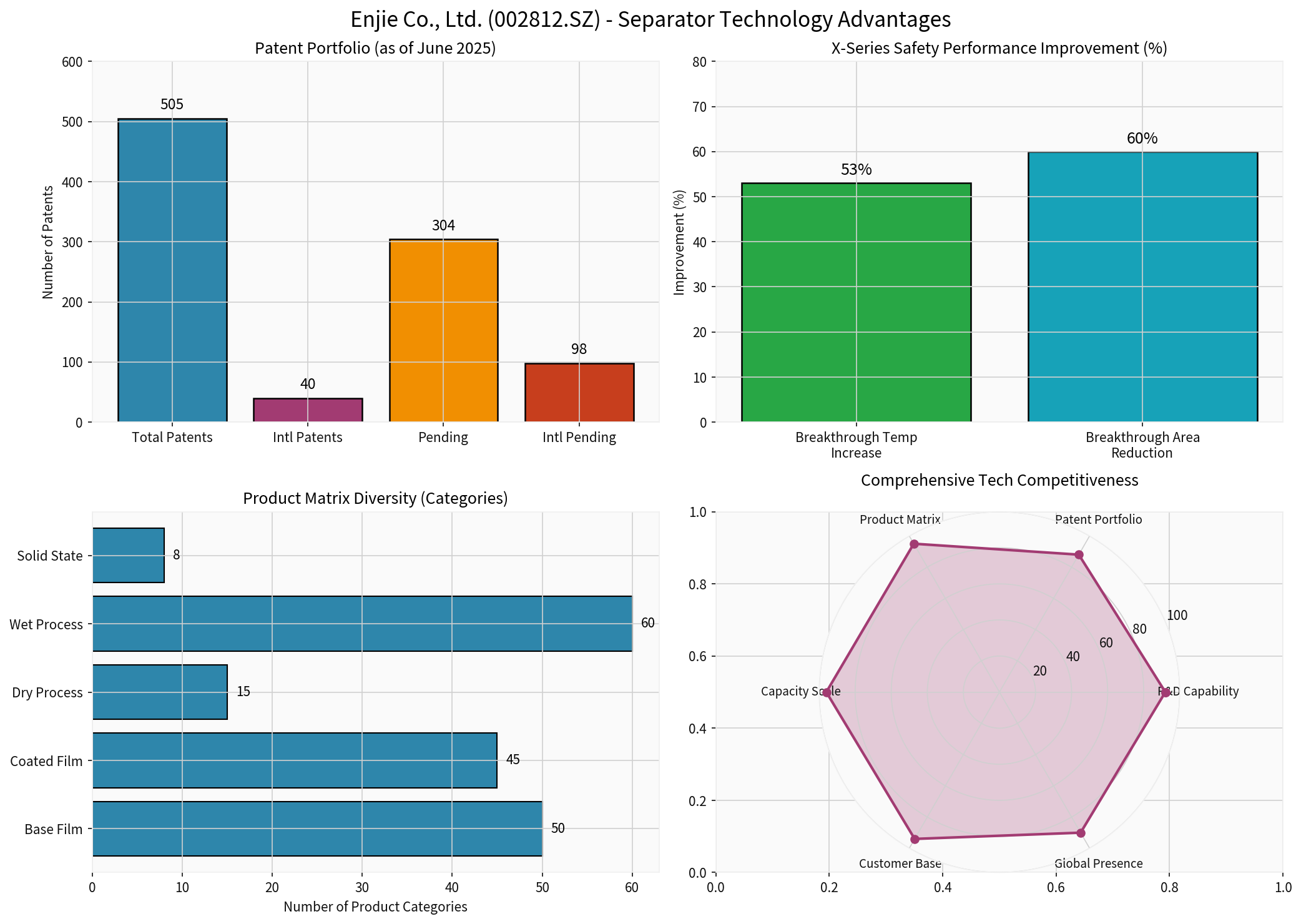

Enjie Co., Ltd. has established a comprehensive intellectual property protection system, providing solid support for customer supply[1]:

| Patent Category | Quantity | Description |

|---|---|---|

| Valid Authorized Patents | 505 |

As of June 30, 2025 |

| International Patents | 40 |

Global patent layout |

| Patents Under Application | 304 |

Continuous innovation |

| International Patent Applications | 98 |

Internationalization strategy |

The company has completed patent layouts in Japan, South Korea, the United States, Europe and other regions, forming a comprehensive technology protection system[1]. This large-scale patent layout not only protects the company’s core technologies, but also constructs high barriers to industry entry.

Enjie Co., Ltd. has a high-quality R&D team[1]:

- R&D personnel with master’s degree or above: Over 150 people

- International R&D team: Includes professional R&D personnel from the United States, Japan, South Korea and other regions

- Core technology R&D team: Covers fields such as separator and coating production equipment, separator preparation processes, raw material improvement, coating processes, slurry formulations, recycling and energy-saving technologies

With nearly 30 years of talent accumulation in the BOPP film industry, which is closely related to the lithium-ion battery separator industry, the company has established a sound talent incentive mechanism and recruits talents globally[1].

Enjie Co., Ltd. continues to carry out technological innovation in the separator field, and has launched a number of leading-performance products[1]:

| Performance Index | Traditional Separator | Series X | Improvement Range |

|---|---|---|---|

| Membrane Breaking Temperature | 150℃ | 230℃ | +53% |

| Membrane Breaking Area | Benchmark | Reduced by 60% | -60% |

Series X provides stronger protection for the safety of lithium batteries, effectively reducing the risk of thermal runaway.

- Improves the wettability valueof the separator

- Enhances ionic conductivity

- Significantly improves battery charging speed

- Meets the growing fast charging demandof batteries

- Ultra-thin design: Only 5μm in thickness

- High strength: Excellent mechanical properties

- Leading performance: Reduces the volume proportion of non-active materials inside the battery, improving battery energy storage capacity

Enjie Co., Ltd. has made forward-looking layouts in the semi-solid and solid-state battery fields[1][2]:

| Subsidiary | Business Direction | Progress Status |

|---|---|---|

| Jiangsu Sanhe | Semi-solid battery separators | Has mass production and supply capacity , actively expanding the market |

| Hunan Enjie | Solid-state battery materials | Focuses on lithium sulfide, sulfide solid electrolytes and electrolyte membrane products |

The lithium sulfide, sulfide solid electrolytes and electrolyte membrane products developed by Hunan Enjie are in a leading position in the industry in terms of core indicators such as

Enjie Co., Ltd. has formed a lithium battery separator product matrix with

| Product Category | Main Applications | Technical Features |

|---|---|---|

| Wet-Process Separators | Ternary batteries, power batteries | Thin and light, high strength, high energy density |

| Dry-Process Separators | Energy storage, LFP batteries, two-wheelers | High melting point, excellent pressure resistance, low cost |

| Coated Separators | High-end power batteries | Customizable, optimized performance |

| Semi-Solid Separators | Next-generation batteries | Mass production achieved |

| Solid-State Electrolytes | Future battery technologies | Leading conductivity |

Enjie Co., Ltd. mainly adopts the wet-process separator technology, which has the following advantages[3]:

| Performance | Wet-Process Technology | Dry-Process Technology |

|---|---|---|

| Thickness Range | 5-30μm | 12-30μm |

| Pore Size Distribution | Narrow and uniform | 15-40μm |

| Porosity | 30%-50% | Relatively high |

| Applicable Scenarios | Demands for thinness, large capacity, high energy density | Energy storage, LFP batteries |

The wet-process technology has high overall process difficulty and precision, which can achieve higher porosity and better air permeability, making it easier to meet the downstream lithium battery demands for thinness, large capacity and high energy density[3].

The company continues to increase the proportion of on-line coating production capacity, and the self-developed equipment project is progressing smoothly. High production yield reduces losses, which is expected to significantly reduce production costs while increasing barriers to production equipment and processes[3].

Enjie Co., Ltd. has successfully passed product certification from most mainstream domestic and foreign lithium battery manufacturers, and has entered the most stringent overseas power battery supply chain system[1]:

- CATL, BYD, CALB, Gotion High-Tech

- EVE Energy, Farasis Energy, Lishen Battery

- Panasonic, LGES (LG Energy Solution)

- ACC (France), Ultium Cells

- Overseas large automakers

In the first half of 2025, the company not only renewed a three-year supply agreement with its long-term overseas key customer LGES, but also signed a supply agreement from 2026 to 2030 with a well-known global U.S. automaker, with an expected procurement of approximately 973 million square meters of lithium battery separators[1].

| Time | Customer | Agreement Period | Procurement Volume |

|---|---|---|---|

| Early 2025 | Beijing Weilan New Energy | 2025-2030 | No less than 300 million square meters (semi-solid/all-solid) + 100 tons of electrolytes |

| Early 2025 | LG Energy Solution | 2025-2027 | Approximately 3.55 billion square meters |

| 2025 | A well-known U.S. automaker | 2026-2030 | Approximately 973 million square meters |

These orders fully reflect the high recognition of the company’s product quality and technical strength by overseas key customers, and also provide a strong guarantee for the future utilization rate of new overseas production capacity[1].

Based on the above analysis, the technical advantages of Enjie Co., Ltd. can be summarized in the following six dimensions:

| Competitiveness Dimension | Score | Evaluation |

|---|---|---|

| R&D Capability | 92/100 | High-intensity investment, over 150 master’s and doctoral talents |

| Patent Layout | 88/100 | 505 valid patents, 40 international patents with global layout |

| Product Matrix | 95/100 | 130+ segmented categories, the most diversified supplier |

| Production Capacity Scale | 96/100 | Expected to exceed 15 billion square meters in 2025, world’s largest |

| Customer Resources | 94/100 | Covers all key domestic and overseas battery manufacturers and automakers |

| Overseas Layout | 90/100 | Bases in Hungary and the United States, overseas revenue accounts for over 20% |

As the global leader in lithium battery separators, Enjie Co., Ltd. has the following core technical advantages:

- Patent Barriers: A technological moat built by 505 valid authorized patents

- Product Innovation: Innovative products such as Series X high-safety base film, Series I high-wettability base film, and 2nd generation 5μm high-strength base film

- Forward-Looking Layout: Mass production of semi-solid battery separators, leading technology in solid-state battery materials

- Customer Recognition: Access to the world’s most stringent overseas power battery supply chains

- Scale Effect: Cost advantages brought by the world’s largest production capacity scale

As the new energy vehicle and energy storage industries continue to develop, the market demand for lithium battery separators will continue to grow, and enterprises with large-scale high-quality production capacity and stable supply capabilities are more likely to be favored by downstream large customers. Enjie Co., Ltd. is expected to further consolidate its global leading position through technological iteration and global layout.

[0] Jinling API - Company Profile Data of Enjie Co., Ltd.

[1] Yunnan Enjie New Materials Co., Ltd. 2025 First Half Annual Report (http://qxb-pdf-osscache.qixin.com/AnBaseinfo/b9823c26539900ff1f0670481cab13ad.PDF)

[2] 2025 Annual Competitive Brand List for Separators in China’s Lithium Battery Industry (https://www.itdcw.com/news/top/10131512J2025.html)

[3] Zheshang Securities - Research Report on Global Layout of Lithium Battery Separator Leader (https://pdf.dfcfw.com/pdf/H3_AP202305111586497043_1.pdf)

[4] Battery China Network - Lithium Battery Separator Orders “Pick Up” (http://www.cbea.com/djgc/202504/149990.html)

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.